Introduction to SEBS TPE and Its Properties

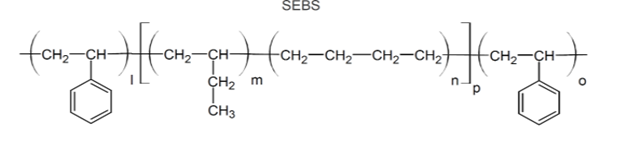

SEBS TPE (Styrene-Ethylene-Butylene-Styrene) is a widely used thermoplastic elastomer that mimics the properties of uncured rubber while offering the processing advantages of thermoplastics. Derived through selective hydrogenation of SBS (Styrene-Butadiene-Styrene) copolymers, SEBS exhibits outstanding heat and UV resistance, excellent elasticity, and good processability. While hydrogenation improves the polymer’s thermal and environmental stability, it may slightly compromise mechanical strength and increase production costs.

Applications and Performance Enhancements

SEBS TPE is frequently used as an impact modifier for engineering thermoplastics andpolypropylene. Its ability to enhance toughness and elasticity makes it a preferred additive in a variety of plastic formulations. To further improve its performance or reduce costs, SEBS is often compounded with oils and fillers.

The applications of This polymer are diverse and span multiple industries. Common uses include hot melt pressure-sensitive adhesives, soft-touch components in toys, and durable soles in footwear. Additionally, SEBS is widely used as a modifier for bitumen in flooring and road paving, where it enhances flexibility and weather resistance under heavy traffic and harsh conditions.

Blending and Industrial Use

By blending This polymer with various thermoplastics, manufacturers can achieve optimized material properties tailored to specific product requirements. This flexibility makes SEBS TPE a valuable choice in industries such as automotive, construction, and consumer goods.

Further Benefits of SEBS TPE in Product Design

Beyond its core mechanical and environmental advantages, This polymer also supports modern product design requirements such as color customization, overmolding capabilities, and compatibility with various manufacturing techniques like injection molding and extrusion. Its soft-touch feel and excellent skin contact properties make it ideal for consumer goods, especially in applications requiring ergonomic or tactile surfaces. Additionally, This polymer is recyclable, making it a more sustainable alternative to traditional rubbers. These attributes position SEBS TPE as a strategic material in the development of next-generation products that demand both performance and aesthetic appeal.